What builders and brain surgeons should have in common Credit: CX magazine.com Credit: CX magazine.com The topic of this post has been keeping me up at night so I am going to get it off my chest. One of my upcoming builds is (of course) a disc-brake gravel bicycle (gravé, not pavé, no grinding here, just floating over the washboard like The Professor over cobbles). Everyone wants one. The data are clear that a disc brake bike should have thru-axles to control frame flex during braking; the rear thru-axle is essentially part of the frame (the front thru-axle is part of the fork). I designed custom rear thru-axle dropouts to accept the Syntace X-12 axle and a derailleur compatible with Shimano/SRAM road and SRAM cyclocross derailleurs. When I was at NAHBS 2015, one of the first bicycles to catch my attention was the Broken Arrow Cyclocross Bicycle by No22 Bicycles because it also uses a Syntace X-12 thru-axle. It was tricky to design a road hangar for the X-12 system, so I was eager to see No22’s take on the problem. However, I was disappointed: The Broken Arrow uses a standard X-12 hangar that was designed for a subset of mountain bike derailleurs, not the SRAM Force CX1 derailleur. At this point, you may have labelled me a obsessive quibbler, but being an obsessive quibbler is important in certain contexts: like brain surgery, flying an airliner, and framebuilding. The rest of this post is about:

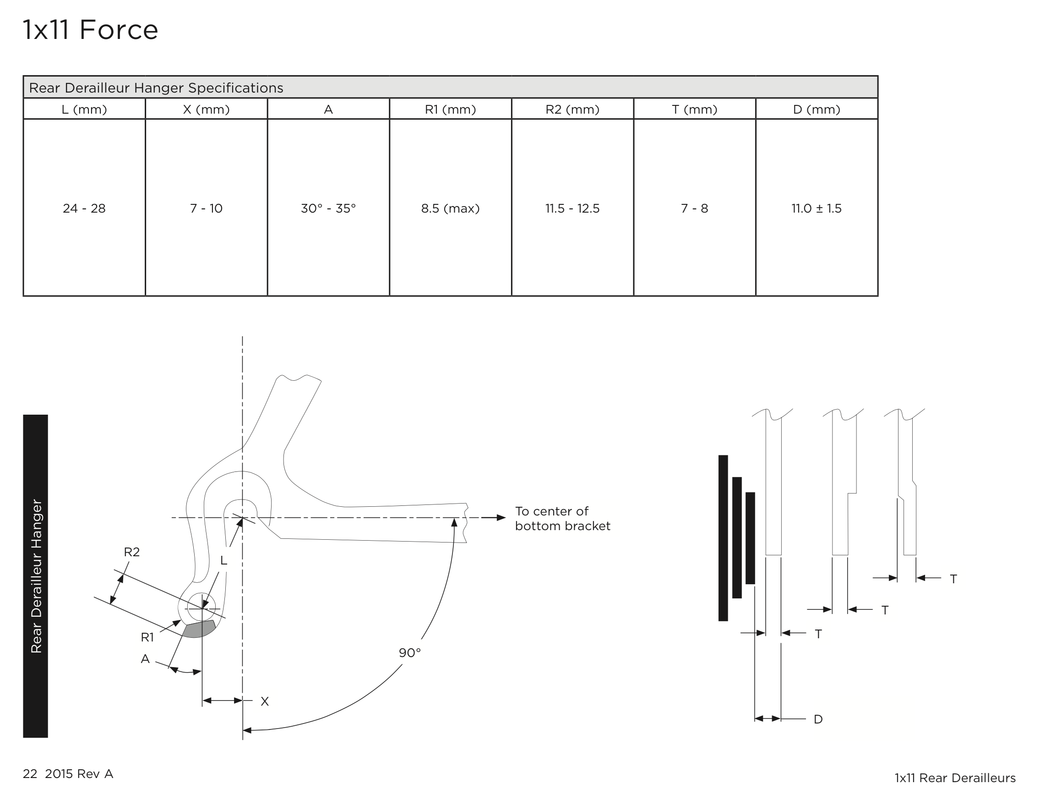

Quibblers forever! Derailleur reviewTo understand why it is not a good idea mount a road derailleur on a mountain bike hangar, here’s a quick review of how rear derailleurs work. All derailleurs work in the same basic way. A parallelogram mechanism changes the linear cable pull (or servo motion) into lateral motion parallel to the rear axle axis, and moves two pulleys mounted on the cage to control chain position along the cassette. The guide pulley (closest to the cassette) moves the chain laterally across the cassette. The tension pulley (furthest from the cassette) pivots on the cage and takes up slack in the chain. The closer the guide pulley is to the cassette, the better the shifting; a consistent distance results in consistent shifting. The more chain that wraps around the cassette before it enters the guide pulley, the lower the chain tension is at the point where it moves from one sprocket to another during the shift. For best shifting, the guide pulley should be as close as possible to the sprockets (without interfering), and wrap as much chain as possible. Park Tool has a more detailed description of derailleur function. Wikepedia also has a good overview of bicycle derailleurs. Mountain and road derailleurs are different To accommodate a wider range of sprocket sizes and take up the corresponding chain slack, mountain bike derailleurs have a different parallelogram design and longer cage. They are generally mounted further down and back relative to the rear axle axis. Relative to the rear axle center axis, the standard Syntace X-12 hangar mounts the derailleur center bolt 16mm back and 31.48mm down, to give a center-to-center distance of 35.6 mm. For its road, 10-speed mountain, and cross rear derailleurs, SRAM recommends 7-10mm back and a maximum center-to -center distance of 28mm (meaning 26.153mm down). Additionally, the tab radius (R1 and R2 in the illustration below) for the Syntace hangar is outside of SRAM's specifications. Thus, the stock Syntace hangar--used on the No22 Broken Arrow--places road derailleurs too far back, too far down, and at the wrong tab angle for optimum shifting. The Métier Vélo custom road hangar is optimized for road derailleursI designed a custom dropout-hangar to accept the X-12 thru-axle and a Syntace-inspired hangar tab (it uses the Syntace breakaway mounting bolt) to place the derailleur within SRAMs recommended specifications: 10mm back and 28mm c-c. Every part on a Métier Vélo frame is custom designed and built for the intended purpose of the frame; 3D-printing means I don’t have to rely on stock parts or outside suppliers. Here's a summary of the quibbling but relevant hangar details:

Sub-optimal design means sub-optimal performance I verified with the SRAM technical crew at NAHBS that a road derailleur mounted outside of the specified range “would not shift well” (I’m not going to name the source because I’m not a reporter and I don’t want to get anyone in trouble). When I asked Michael Smith from No22 about this, he was not familiar with the Syntace specifications, but said the Broken Arrow “shifts great.” However, the bicycle had not yet been raced, and he admitted it had only been ridden on the NAHBS show floor to the photography area. If frame-fit specifications have any meaning, I predict that the Broken Arrow won’t shift well on a muddy cyclocross course under race conditions. I have a feeling the SRAM Force derailleur is going to take the blame, but poor rear shifting on the Broken Arrow is likely because the frame designer did not follow SRAM’s recommendations. Optimal design means optimal performance If you want your bicycle to perform optimally, it needs to be optimally designed, which means the designer must be meticulous about every detail, right down to the number of millimeters your derailleur is from your rear axle. You want a quibbler building your frame, just like you want a quibbler meticulously worrying about how to remove the tumor from your brain. You want parts custom designed and built for the job at hand, and 3D printing allows me to do this for you, every time for every part for every bicycle. Métier Vélo probably will not win any awards (certanly not if the NAHBS cyclocross judges ever read this post), but that is ok, because my inner quibbler knows that I’ve built the best bicycle possible, and that lets me sleep at night. References Derailleurs

http://en.wikipedia.org/wiki/Derailleur_gears http://www.parktool.com/blog/repair-help/rear-derailler-adjustments-derailleur] Syntace X-12 System http://www.syntace.com/ http://www.syntace.com/index.cfm?pid=1&pk=1314 No22 Broken Arrow http://22bicycles.com/collections/bikes/products/broken-arrow-complete http://www.cxmagazine.com/number-22-bicycle-broken-arrow-titanium-cyclocross-bike-nahbs-2015 http://cx.cxmagazine.com/wp-content/uploads/2015/03/no-22-bikes-nahbs-2015-cxmagazine-ayee-nahbs-2015-cxmagazine-ayee-img_0033-edit-edit_1.jpg SRAM Frame Fit Guide for road and cross https://www.sram.com/service/sram/3 https://sram-cdn-pull-zone-gsdesign.netdna-ssl.com/cdn/farfuture/mI5R2tF9I7AdIAsBgUd1FdE029au42ooTa4HUVttVzk/mtime:1408417779/sites/default/files/techdocs/gen0000000004660_rev_a_road_frame_fit_specifications_2015.pdf

0 Comments

Leave a Reply. |

AuthorJamie White Categories

All

Archives

November 2017

UpdatesSubscribeReceive update notices.

|

RSS Feed

RSS Feed