|

Métier Vélo is pleased to offer custom, filament wound carbon fiber tubes from Tim Crossman Cycles. Tim is a framebuilder and custom tube entrepreneur based in Ukraine. Tim selects a carbon filament composition based on your requirements and fabricates a tubeset unique to your needs.

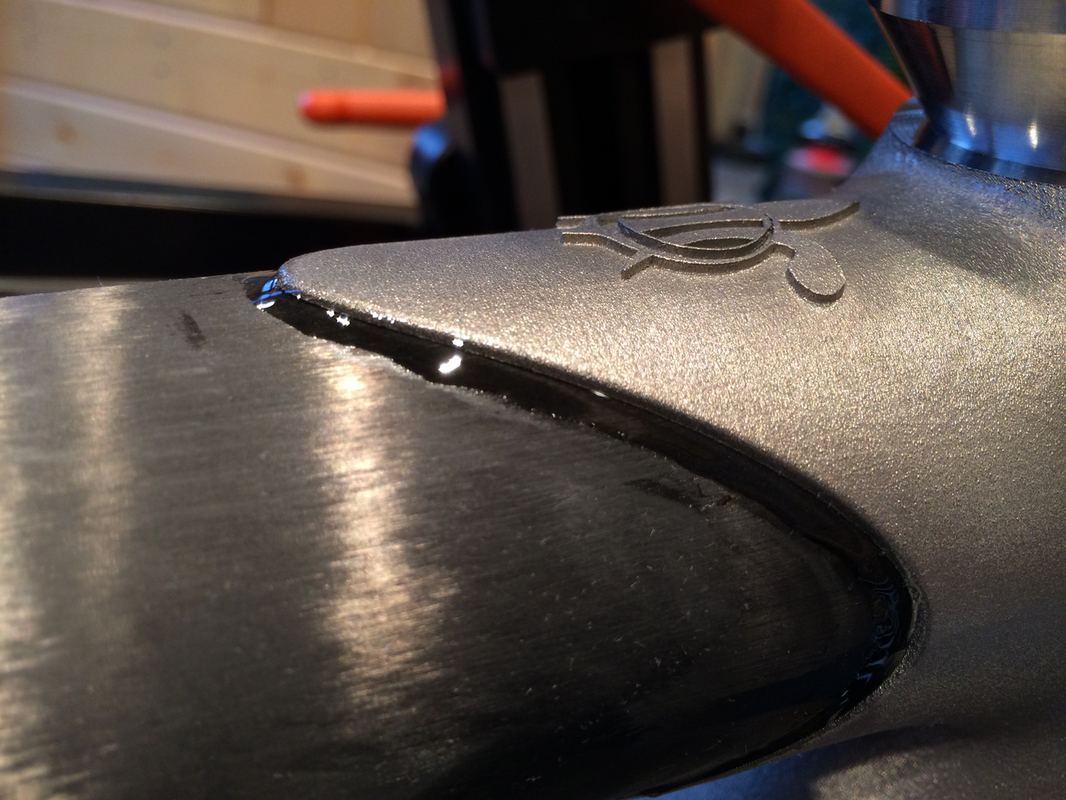

We are excited that Tim has designed a tubeset specifically for Métier Vélo frames. The Métier-Vélo-specific tubes include ovalized, tapered chainstays, a tapered top tube, a seat tube with reinforced clamp region, and super-slim, elegant 11mm seatstays. In addition, Tim Crossman tubes come in a range of standard sizes to meet every rider’s need. Stay tuned for some great frames built with Crossman tubes!

0 Comments

Métier Vélo was recently featured in articles in Bikerumor and CyclingTips. Check them out if you haven't already. Bikerumor features my interview with Anna Schwinn at NAHBS2016. CyclingTips gives a more general overview of 3D printed parts in custom bicycle building. http://www.bikerumor.com/2016/04/05/nahbs-2016-metier-velo-carrer-biwakoguma-journey-and-patrick-in-new-builder-round-up/ http://cyclingtips.com/2016/03/nahbs-2016-3d-printing-hits-its-stride/ For every new frame model, big name bicycle manufactures build a number of prototypes and test them to destruction to see where they fail. But for a small builder doing full custom, every frame is a prototype. Without extensive prototyping and destructive testing, how do you know a frame from a custom builder is safe?

I address safety in five ways:

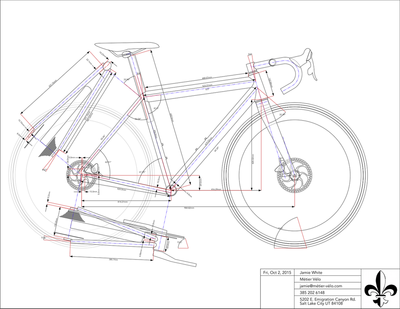

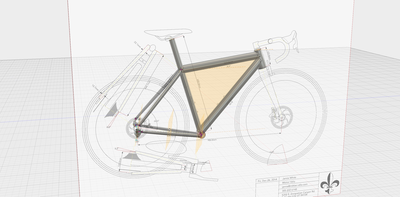

Having made these points, fellow builders at NAHBS 2016 offered to test a frame to failure for me at minimal cost. It is very generous of them. Most likely, the NAHBS Winter Training Bike will be sacrificed sometime this summer. After I do a post-mortem, I'll send the lugs back to GPI for evaluation. I’ll post the results here. In the meantime, read on for more detail. Emma is a professional mountain bike racer and the 2016 Fat Bike National Champion. She needed a road bike. She is very patient. Finally! Emma’s Do-It-All Road Bike features 2x11 compact, wide-range 50/34 11-32 drivetrain, hydro disc brakes, thru-axles front & rear, a custom Syntace X-12 compatible rear dropout system with a hangar optimized for road derailleurs, and clearance for 33mm tubular tires.

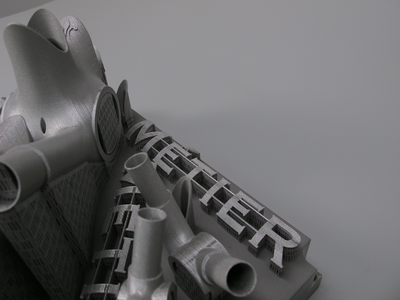

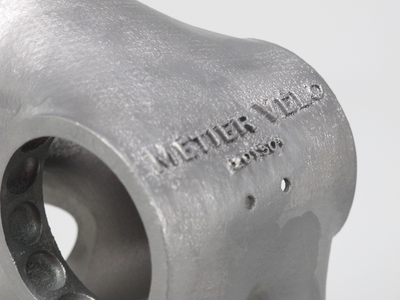

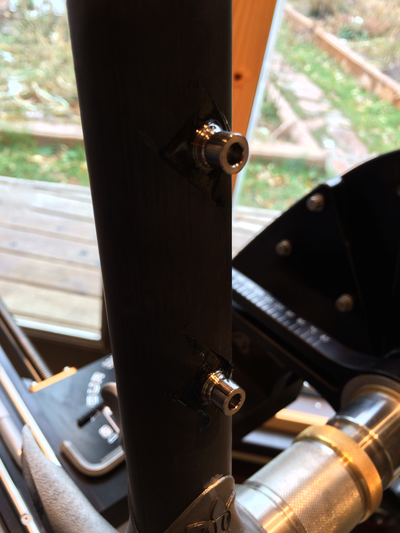

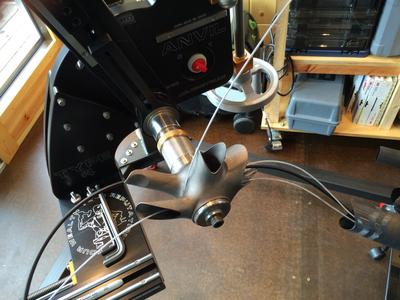

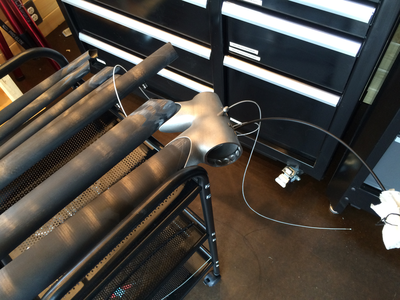

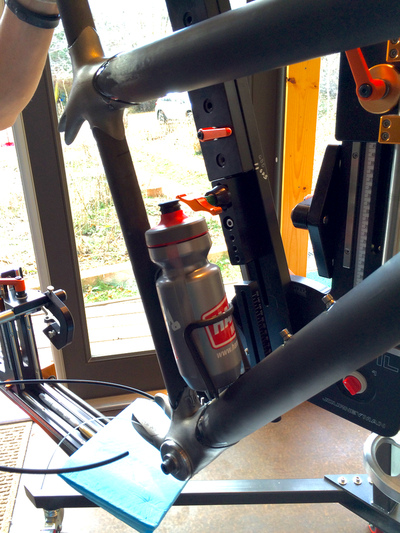

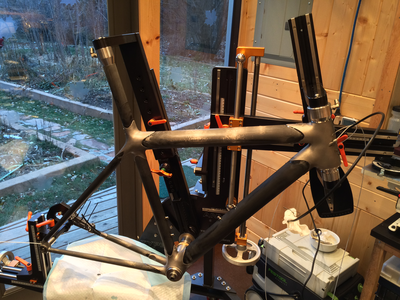

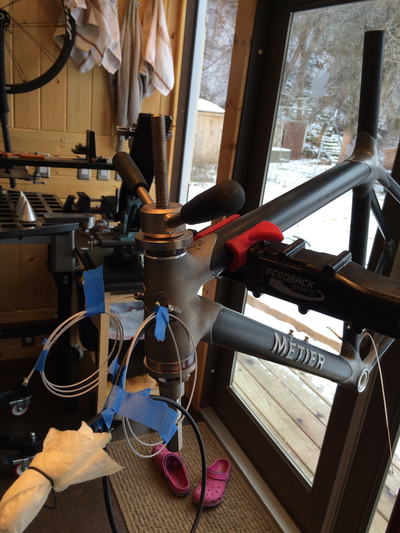

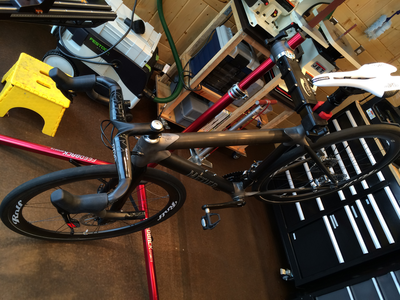

Emma is relatively small, so her frame features stand over clearance provided by an 80mm bottom bracket drop appropriate for 165mm crankarms, and a 421mm seat tube measured bottom bracket center to top-tube center. She sacrificed toe overlap in order to run standard-sized 700c wheel. The 458mm top tube slopes down 12˚ for standover clearance. The rear seatstays are asymmetric; the left kicks back 10mm and up 30mm to accommodate a post-mount brake bridge mount for 160mm rear disc brakes. The relatively short 420mm chainstay, 73.5˚ seat tube angle, and stiff chainstays provide a responsive ride. The bottle mounts keep the center of gravity low; the seat tube bottle bosses straddle the front derailleur clamp. The bosses are titanium from Paragon Machine Works bonded in with vibration-resistant G/Flex. A set of Arundel SideLoaders allow easy access to the bottles. Together, the low bottle mounts, 80mm BB drop, a 71˚ head tube angle, and 48mm of fork rake provide stability on long, rough descents. Cosmetics are printed directly into the lugs or bonded to the frame. The UV-protective finish is easily refreshed. Completing the package are 1) a TRP CX fork, 2) a set of Rolf Prima Ares 4 clinchers mounted with Challenge Strade Bianche “30mm” gravel tires (measured width 32mm) for training, and 3) a set of Rolf Prima Ares 4 tubulars with Challenge Team Edition Chicane 33mm cross tires. #EDIARB The Métier Vélo Winter Training Bike is a disc brake road bicycle with clearance for 33mm tubular tires. The relatively short 420mm chainstay, 73˚ seat and head tube angles, and stiff tubes provide a responsive ride. Seventy millimeters of bottom bracket drop and 48mm of fork rake give a stability on long, rough descents. Cosmetics are printed directly into the lugs or bonded to the frame. The Black-Ti finish of marine vanish and wax protects the carbon composite from UV and is easily refreshed. Displayed at NAHBS 2016!

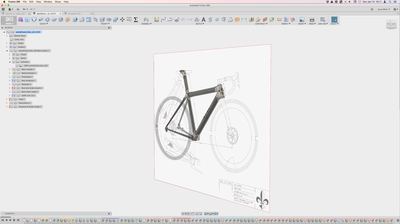

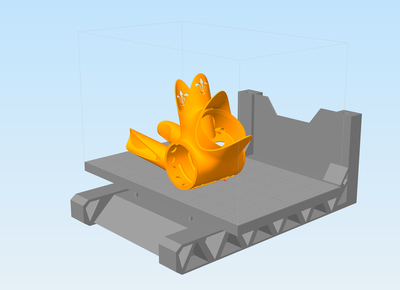

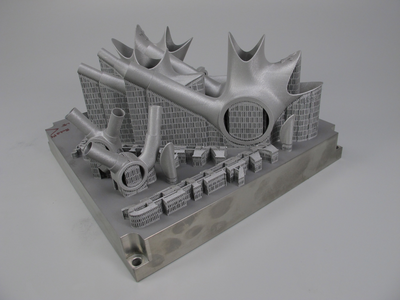

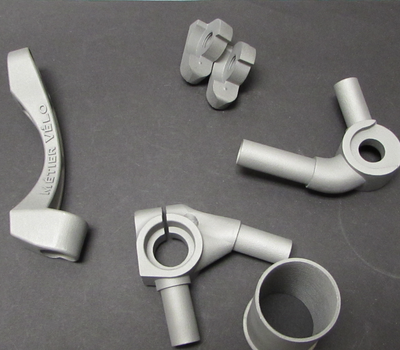

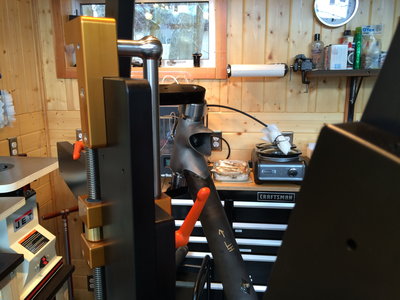

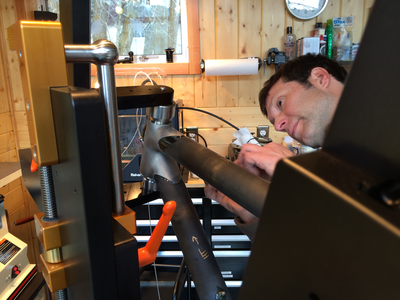

3D printing describes a number of new manufacturing techniques that build a part by adding raw material one layer at a time to the three dimensional design. One advantage of 3D printing is that it allows complex shapes and details (such as cable guides and internal bracing) that can’t be achieved by machining (removing material from a billet) or molding. Métier Vélo uses two 3D printing processes: one for plastic and one for titanium. Printers that make things in plastic are relatively inexpensive so Métier Vélo has its own; the machines that print in titantium are expensive, big, and complex, so for printing the final titanium parts I send the final designs out for production In the shop, I use a MakerBot 2X to rapidly produce plastic prototypes. It prints in durable ABS plastic, so I also use the 2x to produce usable custom plastic parts. Once I have a final design, I send it to GPI Prototype for production in 6/4 titanium. There are important differences between printing in plastic and titanium, and GPI has been super-helpful in making sure Métier Vélo designs produce top-quality parts in titanium. Below are a few photos to give you an idea of the process: This post is as much for my own self-reflection as for your edification. I declined a prestigious fellowship and left a career as a neuroscience researcher to become a framebuilder and start Métier Vélo LLC. Why would I do this? There are a lot of reasons to leave a career in neuroscience research; the main two problems are 1) a glut of highly trained, qualified research scientists (with a Ph.D. and elite postdoctoral training) in the United States, and 2) chronic and severe underfunding of science and research in the U.S. (thanks, Congress). Clearly a bad combination. I won’t go into these problems here because they are boring and I can’t solve them.

The more interesting and relevant question is, why would I become a framebuilder? Here’s some items from the list I made when considering the career switch: |

AuthorJamie White Categories

All

Archives

November 2017

UpdatesSubscribeReceive update notices.

|

RSS Feed

RSS Feed