|

Métier Vélo is pleased to offer lugs and parts 3D-printed by Kanfit 3D Additive Manufacturing. Kanfit 3D prints Métier Vélo designs in 6/4 titanium on an EOS 290 DMP. Kanfit 3D provides all post-processing, including heat de-stressing, machining, and finishing.

Kanfit 3D is based in Israel and manufactures custom parts for aerospace and biomedical applications worldwide. Kanfit 3D meets industry standards for Israeli and international military and commercial aviation, aerospace, and defense, including Israel Aerospace Industries (IAI), Boeing, the Israeli Airforce, and Ministry of Defense. Kanfit 3D lugs and parts can be found in Métier Vélo Team Edition frames, and will debut at NAHBS 2017!

0 Comments

Métier Vélo is pleased to offer custom, filament wound carbon fiber tubes from Tim Crossman Cycles. Tim is a framebuilder and custom tube entrepreneur based in Ukraine. Tim selects a carbon filament composition based on your requirements and fabricates a tubeset unique to your needs.

We are excited that Tim has designed a tubeset specifically for Métier Vélo frames. The Métier-Vélo-specific tubes include ovalized, tapered chainstays, a tapered top tube, a seat tube with reinforced clamp region, and super-slim, elegant 11mm seatstays. In addition, Tim Crossman tubes come in a range of standard sizes to meet every rider’s need. Stay tuned for some great frames built with Crossman tubes! Shimano handles its OEM accounts directly, rather than through a distributor. As a small builder, I wondered if Shimano would be willing to handle a small account. I needn’t have worried; Shimano’s local representative in Park City was very supportive and got Métier Vélo all set up with an OEM account so that I can offer competitive prices on Shimano components. I’ve been riding Dura-Ace pedals since Dura-Ace existed, and I just discovered PRO cockpit components (the carbon bars are really nice), so I’m please to be able to offer Shimano components on Métier Vélo frames.

I prefer to build complete bicycles so that I can make sure everything fits just right. I can build to specifications, but there is nothing like having a part in your hand. Quality Bicycle Products is a national distributor of bicycle components and bike related products. QBP is based in Minnesota, and supplies bicycle shops all over the US with regional distribution centers. QBP is great about supporting small builders; even though Métier Vélo is a small volume operation, QBP was very generous in providing an OEM account. QBP's support is the reason I can equip your Métier Vélo frame with components at competitive prices. QBP supplies Métier Vélo with almost all parts: SRAM and Campagnolo component groups, forks, cockpit components, wheels, and most everything else you can put on your frame. When you order a complete Métier Vélo bicycle, one of the first things I do is order your components so that I have them in-hand while I am designing your frame.

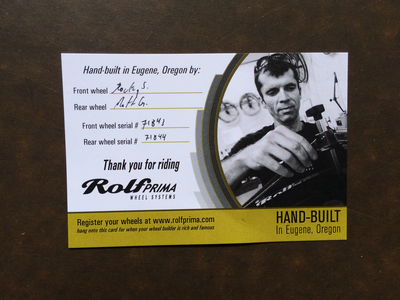

Rolf Prima Wheel Systems hand builds wheels one-at-a time in Eugene Oregon. Rolf Prima fits with the Métier Vélo ethos of building by hand, one-at-a time, using US-sourced parts. You can recognize Rolf Prima wheels by their distinctive paired spoke design. The company, owned by Brian Roddy, is a reincarnation of the original Rolf Prima , which died due to the 2008 financial crisis and subsequent retirement of founder Rolf Dietrich. Each Rolf Prima wheel comes with a card signed by the individual who built it. Rolf Prima wheels are built around their proprietary hubs, most of which are manufactured in the US. The rear hubs feature Differential Flange Diameter to transfer driving forces and a Dish-Reducing Design to further strengthen the rear wheel. Rolf Prima wheelsets have a number of innovative technical features, look great, and have a 2-year warranty. Rolf Prima also has a lifetime crash-replacement program. Rolf Prima has been great to work with and is very supportive of small builders; many of the complete bikes at NAHBS feature Rolf Prima wheels. Métier Vélo has an OEM agreement with Rolf Prima, so you can have really great wheels on your Métier Vélo bicycle at a great price. Two forthcoming Métier Vélo bicycles will feature Rolf Prima wheels: Cross CX thru-axle tubulars on one and another with a set of Ares 4 clinchers built up with thru-axle hub front & rear.

For much of 2015, I’ve been working with GPI Prototype & Manufacturing Services, Inc. to optimize lug design for titanium 3D printing. Designs needed to be optimized for shape, amount of material, and build orientation; GPI was very generous with time and expertise in helping come up with the final lug shapes and other designs. They have been excellent to work with and the quality of the titanium prints continues to exceed my expectations. Titanium printing is pricey, and GPI has worked hard to help reduce the cost of a set of parts by approximately 40%, putting Métier Vélo bicycles in the same price bracket as a top-end manufactured bike from Trek or Cannondale. In addition to bicycle lugs, GPI prints rocket engines, implanted medical devices, among many other cool things. You can learn about GPI in this video (keep an eye out at 36s for a Métier Vélo head tube lug in production). Here are some of the final lugs after printing and cleanup: TRP Brakes are located right up the road from Métier Vélo in Ogden, Utah. TRP makes great OEM and aftermarket brakes. This year TRP came out with a thoughtfully designed thru-axle disc brake front fork for cross and gravel bicycles, one of the first aftermarket thru-axle carbon forks. TRP products often fill design gaps left by the Big Three component manufacturers (SRAM / Shimano / Campagnolo), and they have their own manufacturing facility in Taiwan, which lets TRP rapidly respond to market demands. TRP is a reliable presence at NAHBS, and does a great job of supporting small builders. You’ll find TRP carbon forks and TRP Hy/Rd hybrid cable-hydraulic brakes on upcoming Métier Vélo gravel bicycles. TRP is an OEM supplier for Métier Vélo , so whenever you specify TRP parts on Métier Vélo frames, you’re getting great performance at the best possible price.  Chris King headsets and bottom brackets are standard on Métier Vélo framesets. Chris King headsets and bottom brackets are standard on Métier Vélo framesets. The headset and bottom bracket are part of the soul of the bicycle, and essential for performance and reliability of the frame/fork ensemble. Unless you have very good reasons and can persuade me otherwise, a Métier Vélo frame fuselage (frame and fork together) will have a Chris King headset and bottom bracket pre-installed. Chris King components have a legendary reputation for performance and reliability. They are super-durable, well-designed and of the highest quality, so they have become the de facto standard on a majority of handbuilt custom bicycles. There are very few bicycles at NAHBS that do not use Chris King headsets and bottom brackets. As a business, Chris King Precision Components represents the best of US manufacturing; their parts are made in Portland, Oregon, and they support their community and small builders. My personal experience with Chris King headsets is typical: I have a mountain bike with a Chris King headset that was installed in 1998 and has never needed adjustment; it still feels like new. Chris King backs up their headsets with an unheard-of 10-year warranty, and warranty their bottom brackets for five years. Métier Vélo is a Chris King OEM partner, which means that not only are you getting the best headsets and bottom brackets on your frame, you’re also getting a great deal. Bourbon, Beer & Beautiful Bikes | Wheels, Pieces and Parts I just returned from my second North America Handbuilt Bicycle Show in Louisville, Kentucky. NAHBS does a great job of showcasing custom bicycle builders and the companies that encourage and support them. If you’d like to know more about the show, check out the 2015 NAHBS website or online news coverage at Bikerumor, roadbikereview.com or Cyclocross Magazine. My wife Alexa went with me to keep me company and also on track (focus, Jamie). We had a great time at the show and experiencing a little bit of Louisville.

|

AuthorJamie White Categories

All

Archives

November 2017

UpdatesSubscribeReceive update notices.

|

RSS Feed

RSS Feed